- Home /

- Lubrication /

- Grease /

- SKF grease - high load - extreme pressure

Shop Now

- Abrasives & Drilling

-

Adhesives - Sealants - Paints - Cleaners

- Assortment Kits

- Automotive

- Automotive - Degreaser & Cleaners

- Backing - Impact & Rebuilding Compounds

- Chemical Anchors

- Construction Adhesives

- Contact Adhesives

- Cutting Liquids & Pastes

- Detecting

- Dispensing Tools

- Gasketing & Silicone Sealants

- Graphite Powder

- Hand Cleaner

- Household Cleaners

- Instant Bonding

- Metal Repairs

- Paint

- Primers - Activators - Cleaners

- Retaining

- Structural Bonding

- Tamper Proofing

- Thread Sealing

- Threadlocking

- Welding

-

Bearings & Housings

- Adaptor Sleeves - Lock Nuts & Washers

- Bearing Units (Housing & Bearing Complete)

-

Bearings

- AGRI Hubs

- Ball (Deep Groove)

- Cam Followers

- CARB Toroidal

- Cylindrical Roller Bearing

- Double Row Angle Contact Ball bearing

- Double Row Ball (Deep Grove)

- Self-Aligning Ball Bearing

- Single Row Angle Contact Ball Bearing

- Spherical Plain Bearings

- Spherical Roller

- Spherical Thrust

- Tapered Roller

- Thrust

- Trailer Wheel Bearing Kits

-

Wide Inner Ring (Insert Bearing)

- CSA / KHR / ENR / SAA (Locking Collar - Flat OD - Flat Back)

- CSB (Grub Screw - Flat OD - Flat Back)

- SER / UR / FSB / UCS (Grub Screw - Flat OD - With Snap Ring)

- UC / YAR / UCX (Grub Screw - Extended Inner Ring)

- UK / UKX / YSA (Tapered Bore - suit adapter sleeve)

- YAT / SB / UB (Grub Screw - Flush Back)

- YEL / NA / HC / UEL / EW (Locking Collar - Extended Inner Ring)

- YET / SA / AEL / EN (Locking Collar - Flush Back)

- Bronze Bar

- Bushes

- Circlips - Retaining Rings - E-Clips

-

Housings & Accessories

- Spherical Roller - Housings & Accessories

-

Wide Inner Ring (Insert) Housings

- Cartridge

- End Cover

- F / FX / FY / FYJ (4 Bolt Flanged Square)

- FA (Adjustable Flanged)

- FB (3 Bolt Flanged Bracket)

- FC / FCX / ME (4 Bolt Round Flanged Cartridge)

- FL / FYTB (2 Bolt Oval Flanged)

- HA (Hanger)

- LF / FD / FW / FLCT (2 Bolt Oval Flanged)

- P / PX / SY / SYJ (2 Bolt Pillow Block)

- PA / SYF (Tap Base Pillow Block)

- PF ( Pressed Round)

- PFL (Pressed Oval)

- PFT (Pressed Triangle)

- PP (Pressed Pillow)

- Rubber Inserts

- SB / SBX (Saw Bench)

- T / TU / TUJ / TX (Take-Up)

- TUF (Take-Up Frame)

- Individual Balls (Chrome - Stainless - Carbon)

- Rodends

- Bolts & Fasteners

- Engineering Supplies

- Filters

- Lubrication

-

Materials Handling

- Castors - Wheels - Floor Locks - Tubes

- Conveyors

- Gate Hardware

- Lazy Susan Bearings

-

Lifting

- Beam Clamps

- Boom Cranes

- Chain Blocks

- Chain Slings

- Electric Hoists

- Girder Trolleys

- Lever Blocks

-

Lifting Chain & Components

- Excavator Hooks with Safety Latch - Weld On

- Hammer Type Connecting Links

- Lifting Chain

- Multi Master - Oblong Links

- Pannel Clutches

- Self Locking Hooks - Clevis

- Self Locking Hooks - Eye

- Shortening Clutches - Clevis

- Shortening Grab Hooks - Clevis

- Shortening Grab Hooks - Eye

- Single / Double - Oblong Links

- Sling Hook With Safety Latch - Clevis

- Sling Hook With Safety Latch - Eye

- Swivel Lifting Points

- Swivel Self Locking Hooks - Eye

- Swivel Sling Hooks With Safety Latch - Eye

- Weld On Lifting Lugs

- Lifting Shackles - Eye Nuts - Bolts

- Plate Clamps

- Slings - Flat

- Slings - Round

- Load Restraints

- Matting

- Non Rated - Shackles & Hardware

- Storage

- Trolleys & Tables

- Winches

- Power Transmission

-

Safety

- Eye Protection

- Face Protection

- First Aid

- Footwear

- Hand Protection

- Hazardous Storage Cabinets

- Head Protection

- Hearing Protection

- Height Safety

- Hydration & Sun Protection

- Protective Workwear

- Respiratory Protection

- Sanitiser

- Signage

-

Spills - Absorbents - Bunding

- Absorbent Dispensers

- Absorbent Granules & Neutralisers

- Absorbents

- Bunging & Spill Management

- Drain Protection

- Emergency Sealer

- Empty Wheeled Bins

- Erosion & Sediment Control

- Floor Bunding

- Industrial Wipes

- Portable Containment Bunding

- Spill Booms & Barriers

- Spill Kit Accessories

- Spill Kits

- Spills Kit Refills

- Steps & Ladders

- Tool Safety

- Welding Protection

- Sealing

-

Tools

- Air Tools

- Automotive & Workshop

- Cut - Scrape & Saw

- Gas Tools

- Measuring Tools

- Mounting & Dismounting

-

Pliers & Wrenches

- Adjustable Wrenches

- Cable Cutter Pliers

- Circlip Pliers

- Combination Pliers

- End Cutter Pliers

- Flat Nose Pliers

- Hose Clamp Pliers

- Locking Pliers

- Long Nose Pliers

- Multi Grip Pliers

- Pipe Wrenches

- Pliers Sets

- Riveters

- Side Cutter Pliers

- Speed Wrench

- Striping & Crimping Pliers

- Tin Snips

- Wire Pliers

- Wire Stripers

- Power Tools - 240v

- Power Tools - Battery Driven

- Promo Items

- Screwdrivers - Hex Keys & Fastening

- Sockets - Socket Sets & Accessories

- Spanners & Spanner Sets

- Striking & Prying

- Tool Box Inserts (Tools & Empty)

- Tool Boxes & Storage

- Tool Kits

- Tractor & PTO

- Trailer Parts

SKF grease - high load - extreme pressure

good for harsh & vibration conditions -420 ml cart

Stock Code:

LGEP2/0.4_SKF

$19.32 incl GST

Stock Locations

-

Ballarat:71 In Stock

-

Shepparton:Special Order

Description

LGEP2/0.4

SKF bearing grease LGEP 2 in 420 ml cartridge

SKF LGEP 2 is mineral oil based, lithium soap thickened grease with extreme pressure additives. This grease provides good lubrication in general applications subjected to harsh conditions and vibrations.Typical applications:• Jaw crushers• Heavy machinery, vibrating screens• Crane wheels, sheaves• Work roll bearings in steel industry• Sealed SRBs

- Excellent mechanical stability

- Extremely good corrosion inhibiting properties

- Excellent EP performance

Dimensions

| Product weight | 0.38 kg |

Performance

| Suitable for High load applications | + |

| Suitable for Vertical shaft applications | Ο |

| Suitable for applications with Oscilating movements | Ο |

| Suitable for applications with Severe vibrations | + |

| Suitable for applications that require Rust protection | + |

| Suitable for applications that require Water resistance | + |

| Suitable for applications that require Frequent start-up | ++ |

| Speed (max.) n x dm (x 1000) | 300 |

| Operating temperature range | -20.0 – 110.0 °C |

| Dropping point (min) ISO 2176 | 180 °C |

| Penetration DIN ISO 2137, Worked, 60 strokes (10⻹mm) | 265 - 295 |

| Penetration DIN ISO 2137, Prolonged (max.), 100 000 strokes, 10⻹mm | +50 |

| Mechanical stability - Roll stability, ASTM D1831 (max.) 50 hrs at 80°C, 10⻹mm | +50 |

| Mechanical stability, V2F test, 144 hrs | M |

| Corrosion protection, Emcor, ISO 11007, Distilled water | 0-0 |

| Corrosion protection, Emcor, ISO 11007 modified, Water washout | 0-0 |

| Corrosion protection, Emcor, ISO 11007 modified, 0.5% NaCl | - |

| Water resistance (max.) DIN 51807/1, 3 hrs at 90 °C | 1 |

| Oil separation DIN 51817, 40°C, % | 2-5 |

| Lubrication ability, R2F test B at 120°C | Pass |

| Copper corrosion (max.) DIN 51811 /ASTM D4048, 24 hrs at 100°C | 2 max.at 110°C |

| Rolling bearing grease life (max.) ROF test, L50 life, 10000 r/min, hrs at °C | 1000 at 110°C |

| EP performance - 4 ball - Wear scar (max.) DIN 51350/5, 1400N | 1.4 mm |

| EP performance - 4 ball - Weld load (min.) DIN 51350/4 | 2 800 N |

Properties

| DIN 51825 code | KP2G-20 |

| NLGI consistency class | 2 |

| Thickener | Lithium |

| Colour | Light brown |

| Base oil type | Mineral |

| Base oil viscosity DIN 51562 at 40 °C | 200 mm²/s |

| Base oil viscosity DIN 51562 at 100 °C | 16 mm²/s |

| Shelf life | 5 year |

| Packsize | 420 ml cartridge |

| Available for single point lubrication | yes |

Logistics

| Product net weight | 0.37 kg |

| eClass code | 23-06-01-01 |

| UNSPSC code | 15121902 |

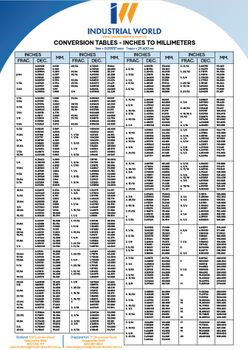

Click here for catalogue information

Lubrication product information

Product Guide Attached

Still can't find what you're looking for? Our website is continuously being updated, so contact us by phone or email for anything else:

Phone:

03 5336 1111

Email:

online@iw.net.au

Details

-

Brand:SKF